Reliable use of canned motor pumps in the chemical industry

Canned motor pumps guarantee maximum safety for man and the environment in the various production processes of the chemical industry. Often designed for extreme conditions, they are used whenever liquids and gases have to be pumped at extreme temperatures and under potentially hazardous conditions. The pumps offer complete reliability – even at the highest pressures and performance levels. They are used whenever conventional technologies reach their limits. High system pressures, large temperature fluctuations, media that is extremely difficult to convey – HERMETIC pumps were developed for such extreme conditions.

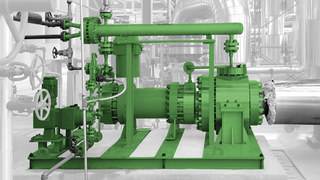

HERMETIC canned motor pump type CNKp 125-100-250B

The second hermetically-sealed containment shell of the canned motor pumps offers completely reliable protection against undesired leakage from the pumps. Also, the canned motor design (which has been well-established for decades) completely avoids the need for shaft seals, conventional bearings and couplings. The result is a high level of operational reliability, hardly any wear and, consequently, a high MTBR (“Mean Time Between Repairs”) value.

HERMETIC canned motor pump type CNKfH+D 150-360 customized design

Preferred applications of hermetic pumps

Canned motor pumps are preferred in the chemical and petrochemical industry, but also for simple pumping tasks, such as circulating pumps in industrial refrigeration equipment.

In general, the following media are conveyed: aggressive, toxic, explosive, hot, cryogenic, malodorous, volatile, flammable or carcinogenic substances – in brief, media that represent an environmental and health hazard.

Read more about the customization of the canned motor pump in our press release.

For attractive 3D representation of the various canned motor pumps and their characteristic functional principles go to our media platform.

Designs and Standards

- Single and multi-stage canned motor pumps according to DIN EN ISO 15783

- API 685 2nd Edition “Medium Duty”

- DIN EN ISO 2858